CHIP RISER - BUILD

The chip riser is a very simple build, but if you have one of the smaller the smaller green boards you're going to have to get things in the right order or you may run into problems.

Firstly you're going to need a chip socket of the appropriate size and two lengths of round turned pin headers, one length for either side of the chip i.e. if you have a 20 pin chip you're going to need two lengths of ten pin headers etc. These are sometimes known as machined headers, but whatever they're called you have to use the round pin versions for this job. Cheaper square pin headers can destroy the chip socket you plug them into by irretrievably bending the sprung contacts to the point that they don't grab onto a chip pin anymore.

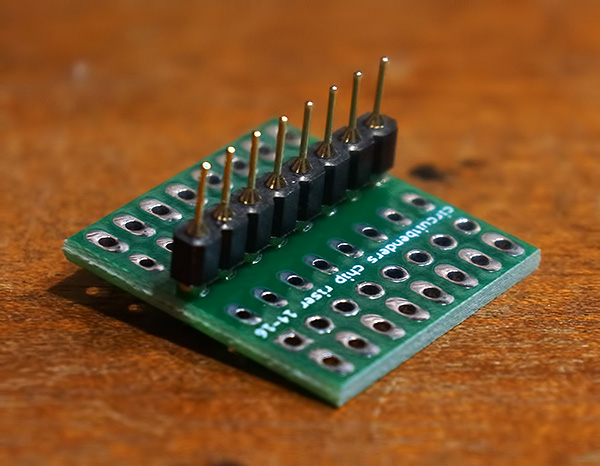

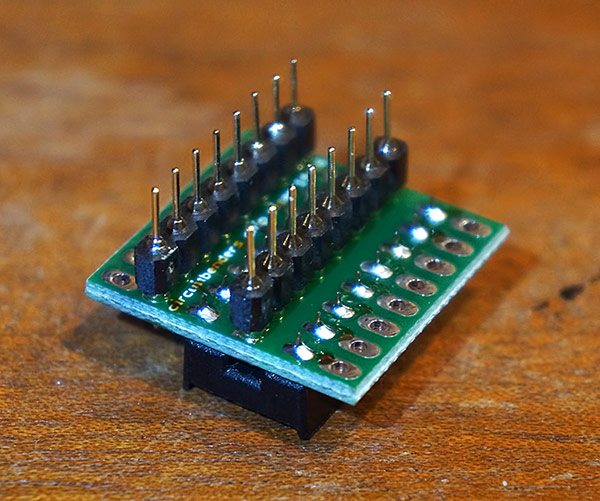

The pin headers are soldered in so they stick out of the underside of the board (the side with the circuitbenders chip riser text). If you have one of the size A, B, or C size green boards you should first solder one length of pin headers into the row of round solder pads between the smaller oval pads where the chip socket will be soldered in, as shown below.

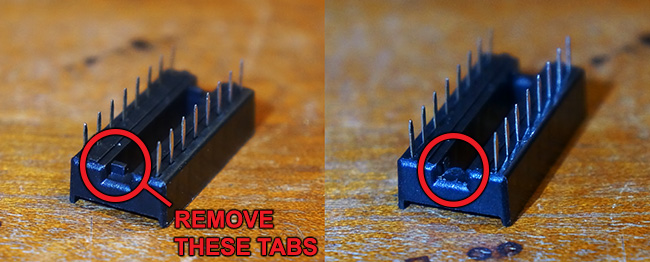

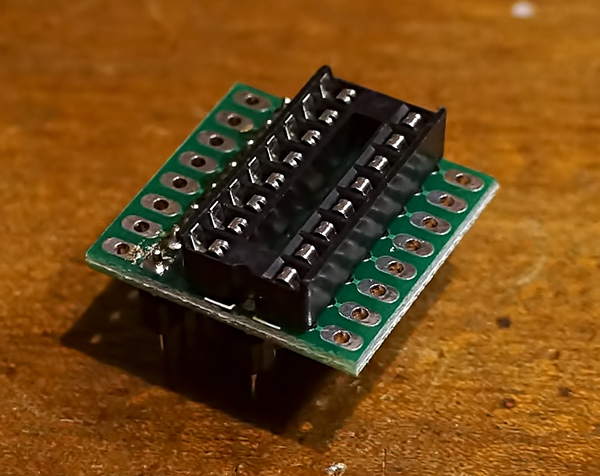

Now you need to look at your chip socket to check that it has the cutout down the middle of the underside. If it has any plastic tags in this space you need to cut them out with a sharp knife. You should do this at both ends and on any central supports. If you don't do this the solder joints from the first row of header pins will prevent you getting the socket flush with the board.

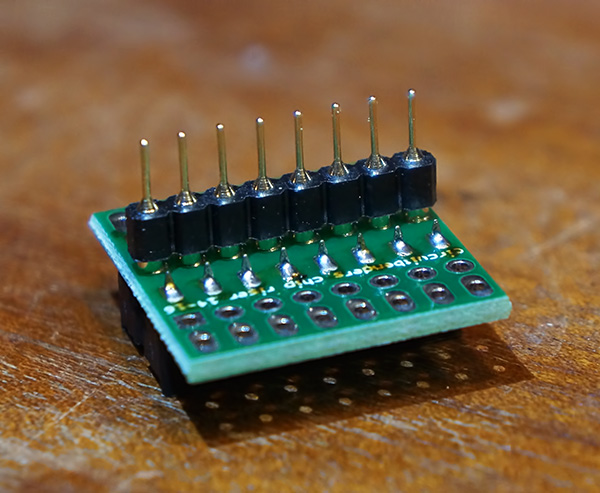

Now solder the socket onto the board on the other side to the header pins, in the position indicated by the silkcreen. The socket solders into the smaller oval solder pads

Finally you need to solder the second strip of header pins into the remaining row of circular solder pads.

You have to solder the header pins and the socket in the specified order. If you solder the socket first then you won't be able to get to the solder pads for the header pin strip thats mounted under the socket. If you solder both the strips of header pins in first then its very difficult to get your soldering iron in between the pins to the solder the socket in without melting something.

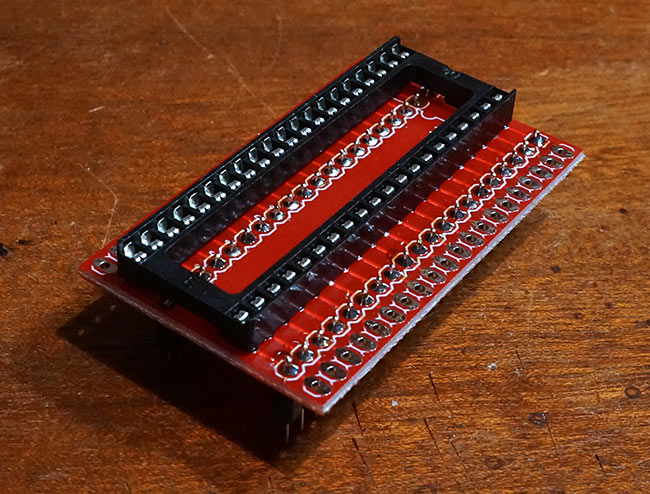

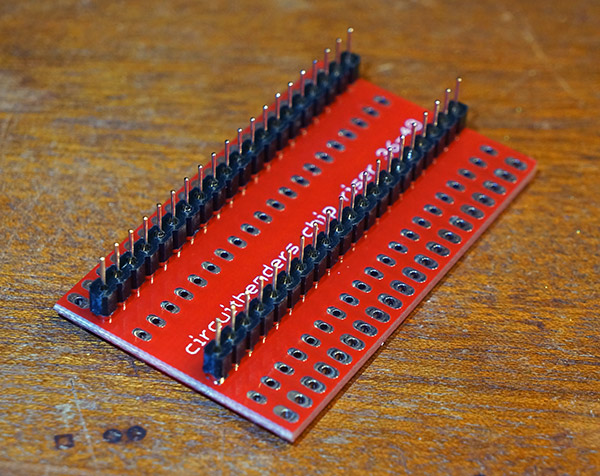

If you have one of the larger size D or E boards you should just solder in the header strips into both the rows of circular solder pads as below. The pins should be on the 'circuitbenders chip riser' text side.

Then just solder your chip socket into the smaller oval pads and you're done.